In the ever-evolving pharmaceutical industry, one principle stands above all — trust in data. From clinical trials to product release, data serves as the foundation for quality decisions and regulatory compliance. This is where ALCOA+ comes into play — a globally recognized framework that ensures data integrity across all aspects of pharmaceutical operations.

But what exactly is ALCOA+?

Why is it crucial for your Pharmaceutical Quality Management System (QMS)?

Let’s dive in.

What is ALCOA+?

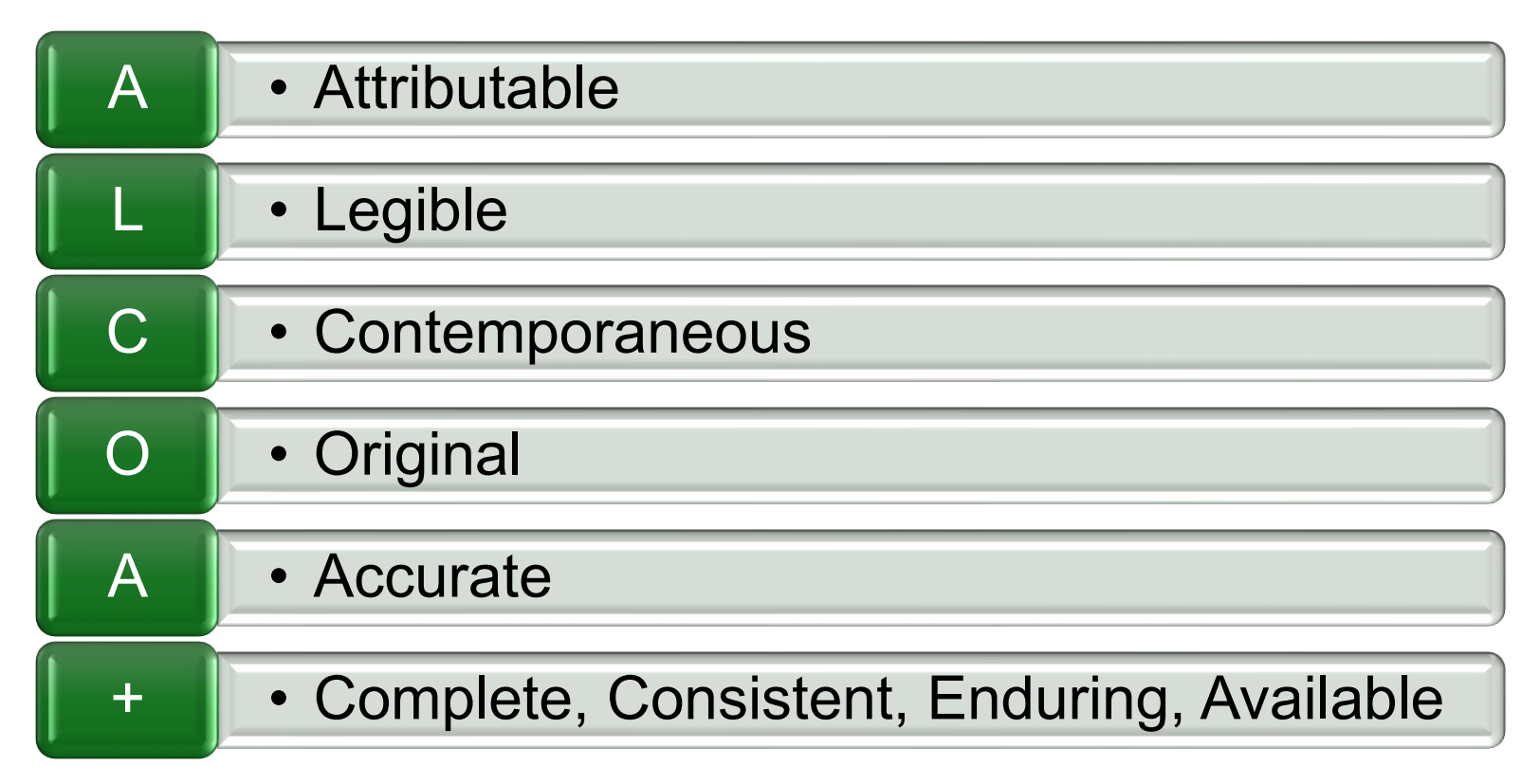

ALCOA is an acronym coined by the FDA, which outlines the core principles of data integrity. It originally stood for:

- Attributable

- Legible

- Contemporaneous

- Original

- Accurate

Over time, industry best practices extended it to ALCOA+, which includes additional criteria that further strengthen data governance:

- Complete

- Consistent

- Enduring

- Available

Together, these principles form the backbone of reliable documentation, ensuring data is not only compliant but also trustworthy.

Why ALCOA+ Matters in Pharmaceutical QMS

Data integrity is not just a regulatory buzzword — it’s a compliance essential. Inadequate data controls can lead to batch failures, warning letters, import bans, or even product recalls. ALCOA+ provides a standardized approach to ensure that data — whether electronic or paper — meets the expectations of global regulatory bodies such as the FDA, EMA, WHO, and MHRA.

Integrating ALCOA+ into your QMS means you are:

✅ Enhancing traceability and accountability

✅ Reducing compliance risks

✅ Building confidence with auditors and inspectors

✅ Ensuring patient safety and product quality

Real-World Application of ALCOA+

Let’s take a practical view. Imagine a lab analyst records HPLC results on a sticky note and later transcribes them into a system. That data is:

✖ Not Attributable (no original link to the analyst)

✖ Not Contemporaneous (recorded after the fact)

✖ Not Original (not the first place where data appeared)

A clear violation of ALCOA+.

Now contrast that with a validated Laboratory Information Management System (LIMS) that auto-records results, timestamps them, and links to a unique user ID. That’s a robust ALCOA+ implementation — secure, traceable, and compliant.

Implementing ALCOA+ in Your QMS

To effectively embed ALCOA+ into your pharmaceutical quality system:

- Train Personnel: Ensure that everyone understands the meaning and importance of ALCOA+ principles.

- Audit Systems: Evaluate both electronic and paper-based systems for gaps in data integrity.

- Validate Software: Ensure that all critical systems (e.g., LIMS, CDS, ERP) are validated and 21 CFR Part 11 compliant.

- Revise SOPs: Align your standard operating procedures with ALCOA+ expectations.

- Conduct Periodic Reviews: Perform regular internal audits and data integrity assessments.

ALCOA+ and the Future of Compliance

As regulators tighten their focus on data integrity, ALCOA+ will remain a non-negotiable standard. It is not just a guideline — it’s a strategic tool that strengthens your QMS, supports regulatory inspections, and upholds patient safety.

Pharmaceutical companies that prioritize ALCOA+ aren’t just ticking a compliance box — they’re investing in a culture of quality and transparency.

Final Thoughts

In a world where data drives every decision, ALCOA+ is the compass that keeps your quality system on course. It ensures that your pharmaceutical operations don’t just meet regulatory requirements but exceed them with confidence.

So ask yourself — is your QMS ALCOA+ ready?